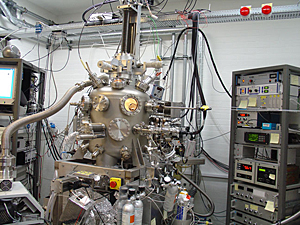

This UHV chamber is equipped with an Århus type STM and facilities for AES/SAM and QMS/TPD. An e-beam evaporator allows for deposition of up to four different metals. There are also facilities for sputtering, heat treatment and gas exposure.

This UHV chamber is equipped with an Århus type STM and facilities for AES/SAM and QMS/TPD. An e-beam evaporator allows for deposition of up to four different metals. There are also facilities for sputtering, heat treatment and gas exposure.

This equipment is used to study the relationship between structure and reactivity of surfaces and alloys, like the role of well-defined step edges in catalytic reactions. A transfer system enables sample transfer to other UHV chambers or to the electrochemistry lab for electrochemical reactivity measurements.

This set-up has its own homepage (click here or on the photo to be redirected) where more detailed information on the equipment is available.